Blog

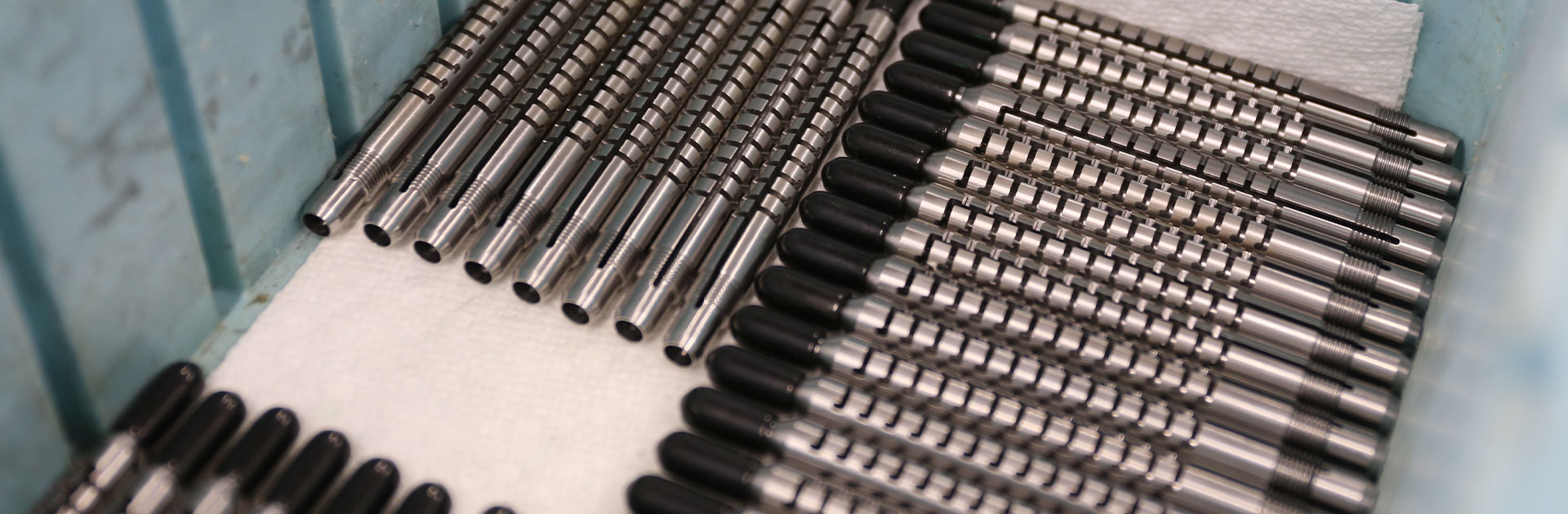

The Machining Elements of Spine Implants

Precision machining plays a crucial role in the production of medical implants, particularly spine implants. As engineers, it’s important for us to understand the significance of precision machining in this field and how it contributes to the overall quality and functionality of spine implants. Precision machining involves the use of advanced machinery and techniques to […]

Read More

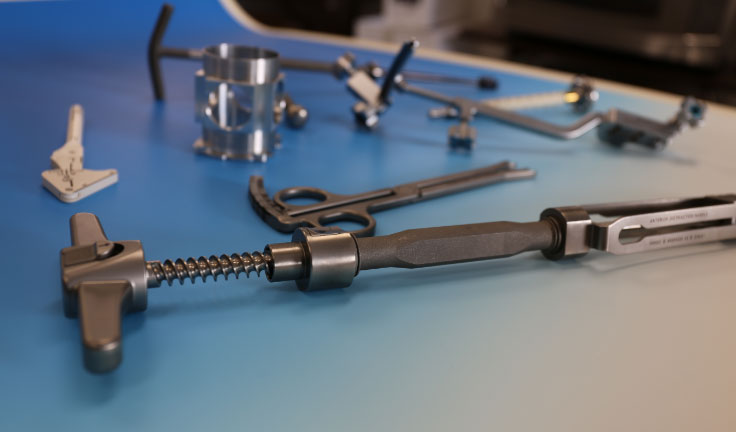

Precision Machining And Spine Implants

Precision machining plays a vital role in treating spinal injuries or diseases; it is composed of various components like plates, screws, and rods. These components stabilize the spine, ensure safety, and promote healing. The meticulous manufacturing process, which involves high-precision machining, plays a significant role in this healing process by providing the effectiveness and reliability […]

Read More

Medical Device Precision Machining for Surgical Instruments

Precision machining is crucial in producing high-quality medical devices, particularly surgical instruments. The demand for precise, reliable, and efficient surgical instruments has increased significantly as healthcare providers strive to improve patient outcomes and minimize surgical complications. This has led to a growing focus on using advanced manufacturing techniques, including precision machining, to produce intricate and […]

Read More

Understanding Quality Control in Contract Manufacturing

In the manufacturing world, maintaining high quality is crucial to the success of any product. When a company decides to outsource its manufacturing processes to a contract manufacturer, like Unity Precision Manufacturing, a robust quality control system is essential to ensure that the final product meets the required standards. Quality control in contract manufacturing involves […]

Read More

What Is Anodizing?

Anodizing is a process in which a protective oxide layer is applied to the surface of a metal object. This layer is created by an electrochemical reaction that converts the metal surface into a durable and corrosion-resistant coating. Anodizing is commonly used in manufacturing a wide range of products, including consumer electronics, medical and aerospace […]

Read More

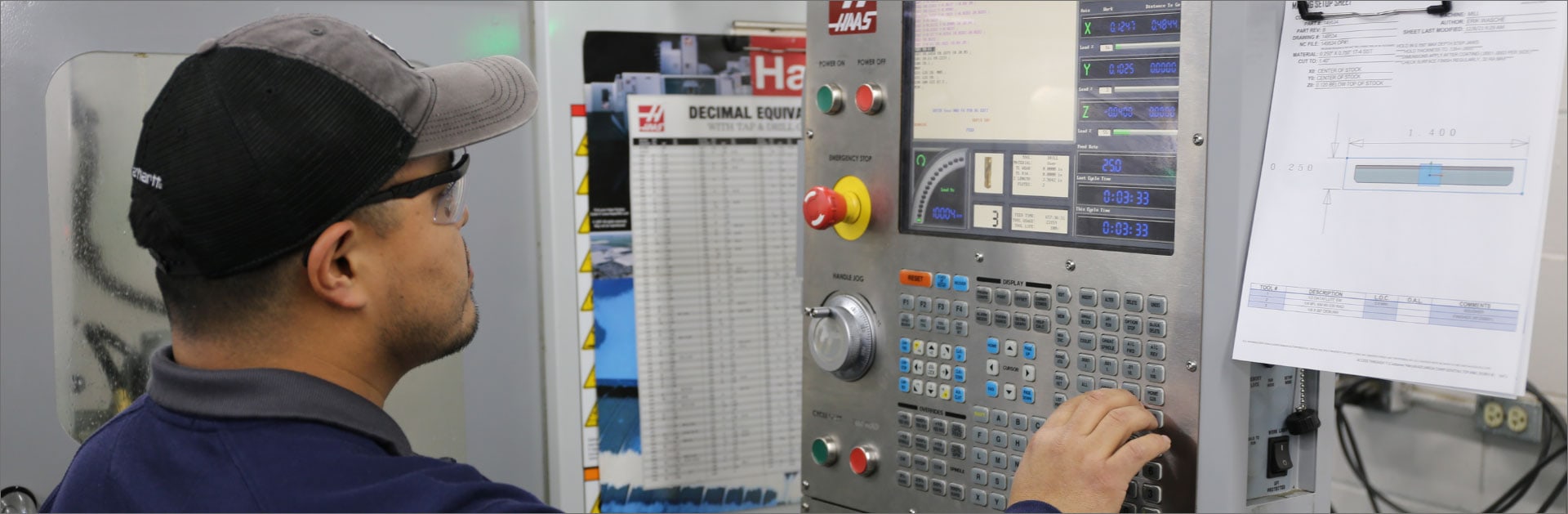

Precision Machining

Precision machining is a manufacturing process that uses advanced machining technology and techniques to create highly accurate and complex parts. It is used in various industries, including aerospace, medical, automotive, and electronics. The process of precision machining involves the use of computer-aided design (CAD) software to create a 3D model of the part. This model […]

Read More

Surface Finish Matters

Surface finishes play a crucial role in the quality of machined parts. A surface finish can affect the component’s durability, appearance, and performance. Therefore, it is essential to understand the importance of surface finishes and how they are achieved in a precision machine shop. Surface finish refers to the texture or roughness of a material’s […]

Read More

Three Essential Materials For Medical Devices

Materials matter greatly in the medical technology industry, especially in machining. This blog will discuss some commonly used materials in medtech machining, such as titanium, aluminum, and stainless steel. Titanium is a popular choice for medical implants and devices because it is biocompatible and corrosion-resistant. It is also lightweight yet strong, making it an ideal […]

Read More

The Importance Committing To 1 OEM

Precision and care are of the utmost importance when developing a medical device. Every detail must be considered from the design phase to the final production to ensure the device is safe and effective. This is where an experienced contract manufacturer becomes a crucial partner. An experienced contract manufacturer has the technical know-how to guide […]

Read More

CNC Milling Applications for Medical Device Precision Machining

Click to Expand CNC milling is a highly precise and advanced manufacturing process that removes material from a workpiece using sophisticated computer-controlled machinery. This cutting-edge technology creates intricate and customized components with extremely tight tolerances, ensuring the dependable and safe operation of medical devices. Here are some examples of CNC milling applications that are used […]

Read More