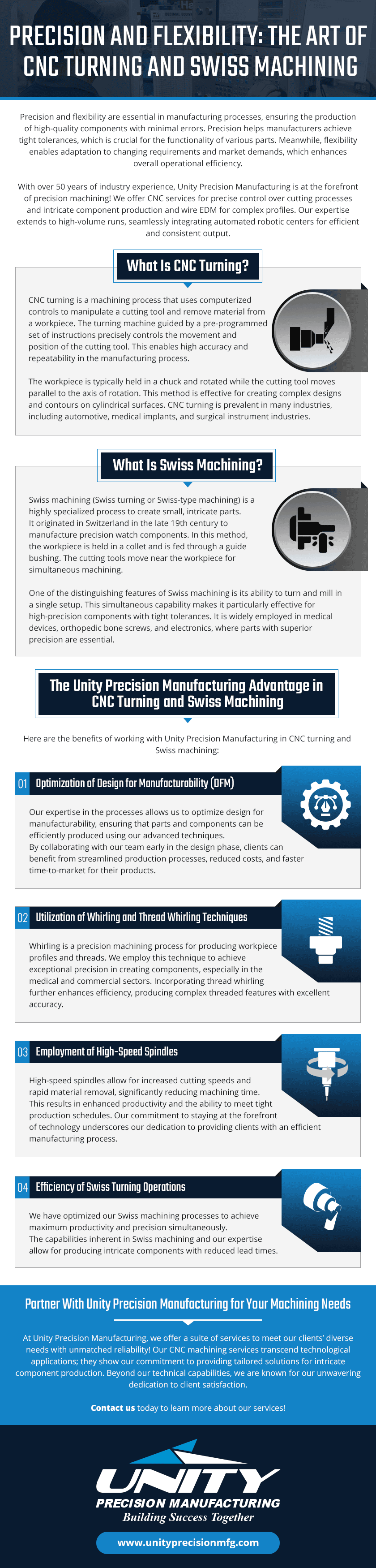

Precision and Flexibility:

The Art of CNC Turning and Swiss Machining

Precision and flexibility are essential in manufacturing processes, ensuring the production of high-quality components with minimal errors. Precision helps manufacturers achieve tight tolerances, which is crucial for the functionality of various parts. Meanwhile, flexibility enables adaptation to changing requirements and market demands, which enhances overall operational efficiency.

With over 50 years of industry experience, Unity Precision Manufacturing is at the forefront of precision machining! We offer CNC services for precise control over cutting processes and intricate component production and wire EDM for complex profiles. Our expertise extends to high-volume runs, seamlessly integrating automated robotic centers for efficient and consistent output.

What Is CNC Turning?

CNC turning is a machining process that uses computerized controls to manipulate a cutting tool and remove material from a workpiece. The turning machine guided by a pre-programmed set of instructions precisely controls the movement and position of the cutting tool. This enables high accuracy and repeatability in the manufacturing process.

The workpiece is typically held in a chuck and rotated while the cutting tool moves parallel to the axis of rotation. This method is effective for creating complex designs and contours on cylindrical surfaces. CNC turning is prevalent in many industries, including automotive, medical implants, and surgical instrument industries.

What Is Swiss Machining?

Swiss machining (Swiss turning or Swiss-type machining) is a highly specialized process to create small, intricate parts. It originated in Switzerland in the late 19th century to manufacture precision watch components. In this method, the workpiece is held in a collet and is fed through a guide bushing. The cutting tools move near the workpiece for simultaneous machining.

One of the distinguishing features of Swiss machining is its ability to turn and mill in a single setup. This simultaneous capability makes it particularly effective for high-precision components with tight tolerances. It is widely employed in medical devices, orthopedic bone screws, and electronics, where parts with superior precision are essential.

The Unity Precision Manufacturing Advantage in CNC Turning and Swiss Machining

Here are the benefits of working with Unity Precision Manufacturing in CNC turning and Swiss machining:

✔ Optimization of Design for Manufacturability (DFM)

Our expertise in the processes allows us to optimize design for manufacturability, ensuring that parts and components can be efficiently produced using our advanced techniques. By collaborating with our team early in the design phase, clients can benefit from streamlined production processes, reduced costs, and faster time-to-market for their products.

✔ Utilization of Whirling and Thread Whirling Techniques

Whirling is a precision machining process for producing workpiece profiles and threads. We employ this technique to achieve exceptional precision in creating components, especially in the medical and commercial sectors. Incorporating thread whirling further enhances efficiency, producing complex threaded features with excellent accuracy.

✔ Employment of High-Speed Spindles

High-speed spindles allow for increased cutting speeds and rapid material removal, significantly reducing machining time. This results in enhanced productivity and the ability to meet tight production schedules. Our commitment to staying at the forefront of technology underscores our dedication to providing clients with an efficient manufacturing process.

✔ Efficiency of Swiss Turning Operations

We have optimized our Swiss machining processes to achieve maximum productivity and precision simultaneously. The capabilities inherent in Swiss machining and our expertise allow for producing intricate components with reduced lead times.

Partner With Unity Precision Manufacturing for Your Machining Needs

At Unity Precision Manufacturing, we offer a suite of services to meet our clients’ diverse needs with unmatched reliability! Our CNC machining services transcend technological applications; they show our commitment to providing tailored solutions for intricate component production. Beyond our technical capabilities, we are known for our unwavering dedication to client satisfaction.

Contact us today to learn more about our services!