As a leading contract manufacturing company with global reach, Unity Precision Manufacturing caters to a broad cross-section of industries. Since 1969, we’ve refined our contract assembly capabilities to provide clients throughout the medical, commercial, and industrial sectors with prompt, high-quality, and dependable services.

Contract Assembly

Overview of Our Complex Assembly Process

Our ISO 9001 and ISO 13485 certifications demonstrate our strict adherence to international standards for quality management systems and medical device manufacturing. We prioritize building enduring customer relationships, founded on close collaboration and transparency. As a third-generation, family-owned business, we know the importance of trust in industries that depend on exceptional product quality and timely delivery.

Detailed Complex Assembly Process Capabilities

Unity Precision’s contract assembly process comprises a full suite of capabilities:

Using CNC milling, turning, and other advanced techniques like Swiss machining, we manufacture parts in-house.

We utilize purchased or client-sourced parts as necessary to deliver optimal product quality and precision.

Our plating, tumbling, blasting, and coating services enhance part durability and aesthetics.

We assemble products using a combination of screwing, welding, press fitting, and/or gluing processes.

We perform functionality testing on all assemblies based on your industry standards.

Laser marking ensures regulatory compliance and product traceability.

We conduct inspections to verify the precision and quality of the assembled product.

Final products are packaged and shipped to the customer according to their production timeline.

Throughout our contract assembly process, we implement Kanban lean manufacturing models to streamline production efficiency.

Medical Assembly Services

Unity Precision uses advanced CNC milling, CNC turning, Swiss machining and assembly methods to produce finished medical products that meet the industry’s strict requirements for functionality and safety. We are ISO 13485 certified, ISO 9001 certified, and FDA compliant with a facility that includes automation and high-end quality controls to ensure precision at every stage of production. We also specialize in manufacturing and assembling Class II and III disposable medical devices, various types of medical instruments, as well as implants with meticulous attention to detail.

Assembly Services for Medical Devices & Instruments

In order to create high-quality surgical instruments, Unity Precision uses state-of-the-art equipment and techniques. That’s why we maintain a fully modernized production facility, complete with temperature controls. We also provide in-house laser marking to meet complex industry standards for traceability and other medical regulations.

Assembly Services for Medical Implants

Our industry expertise extends to assembling specialized medical components, such as orthopedic implants for the spine, joints, bones, and more.

Industrial & Commercial Assembly Services

Unity Precision’s contract assembly services also serve industrial and commercial applications. Our cutting-edge facility and multi-talented workforce are more than capable of providing high-quality assemblies for numerous commercial sectors.

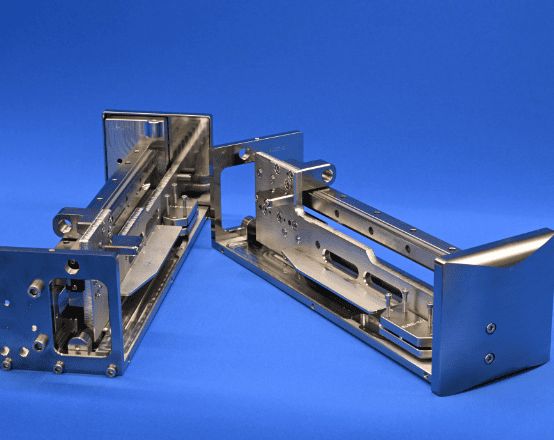

Assembly Services for OEM Manufacturers

We create assemblies that often serve as sub-assemblies for larger products. For instance, we can screw, weld, and/or press together smaller mechanical components that OEM manufacturers incorporate into larger designs. Our streamlined production methods help OEMs improve efficiency and lower costs. With robust quality assurance processes, we assemble parts and products that meet OEM standards for performance and durability.

Assembly Services for Machine Tool Accessories

We manufacture and precisely integrate tooling accessories to enhance machining efficiency. With total adherence to ISO 9001 requirements, Unity Precision provides machine tool accessories that meet strict quality standards.

High Quality Complex Assembly Services From Unity Precision

As one of the leading contract manufacturers in the United States, Unity Precision is committed to your success. Our top-tier contract assembly services can accommodate even the most complex components and adapt to a wide range of medical, industrial, and commercial needs. Contact us today to learn how we can collaborate on your next project.