Commercial & Industrial Applications

Since 1969, Unity Precision Manufacturing has been an industry-leading provider of industrial and commercial contract manufacturing solutions, specializing in making precision-machined components for the following industries:

Electronics

Machinery, machine tools and accessories

OEMs

Photography

Printing

Mechanical parts for sporting equipment

Automotive

As a trusted partner for companies seeking to contract out their production needs, our team is committed to delivering consistent quality, precision, and customer satisfaction. This comprehensive guide will explore the advantages of partnering with a trusted contract manufacturer, Unity’s commercial contract manufacturing solutions, and our proven expertise in the various industries we serve.

Overview of Commercial Contract Manufacturing

Commercial contract manufacturing occurs when a third-party contract manufacturer enters a business arrangement with a brand owner or company to produce products on their behalf. The contract manufacturer is responsible for either part of or all the following manufacturing responsibilities:

- Sourcing materials

- Manufacturing

- Assembling components

- Quality control

Commercial contract manufacturing enables businesses to outsource their production needs to reduce expenses and improve their bottom line. The arrangement can also provide access to specialized expertise and equipment that businesses may not have in-house.

Many companies are beginning to partner with reputable contract manufacturers to improve efficiency and streamline operations, allowing the company to focus on marketing, sales, design, and other core competencies.

At Unity, our process encompasses every step of contract manufacturing, from the initial product concept and design for manufacturability (DFM) to production, packaging, quality inspection, and shipping. We work closely with our clients to ensure successful outcomes within the required timeline.

Industrial Applications of Our Commercial Contract Manufacturing Solutions

Unity manufactures parts and assemblies for a wide variety of industries, such as:

- Industrial & Commercial machinery

Industrial / Commercial machinery

We produce a diverse range of parts and components for the unique needs of commercial equipment.

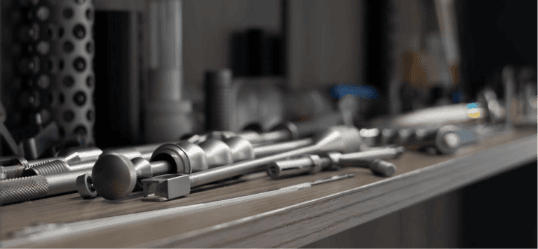

- Machine tools & accessories

Machine tools & accessories

With decades of industry experience, we can manufacture precise tight-tolerance parts for a broad range of machine tools and accessories.

- OEM

OEM

We work closely alongside original equipment manufacturers (OEMs) to support their product development with top-quality components.

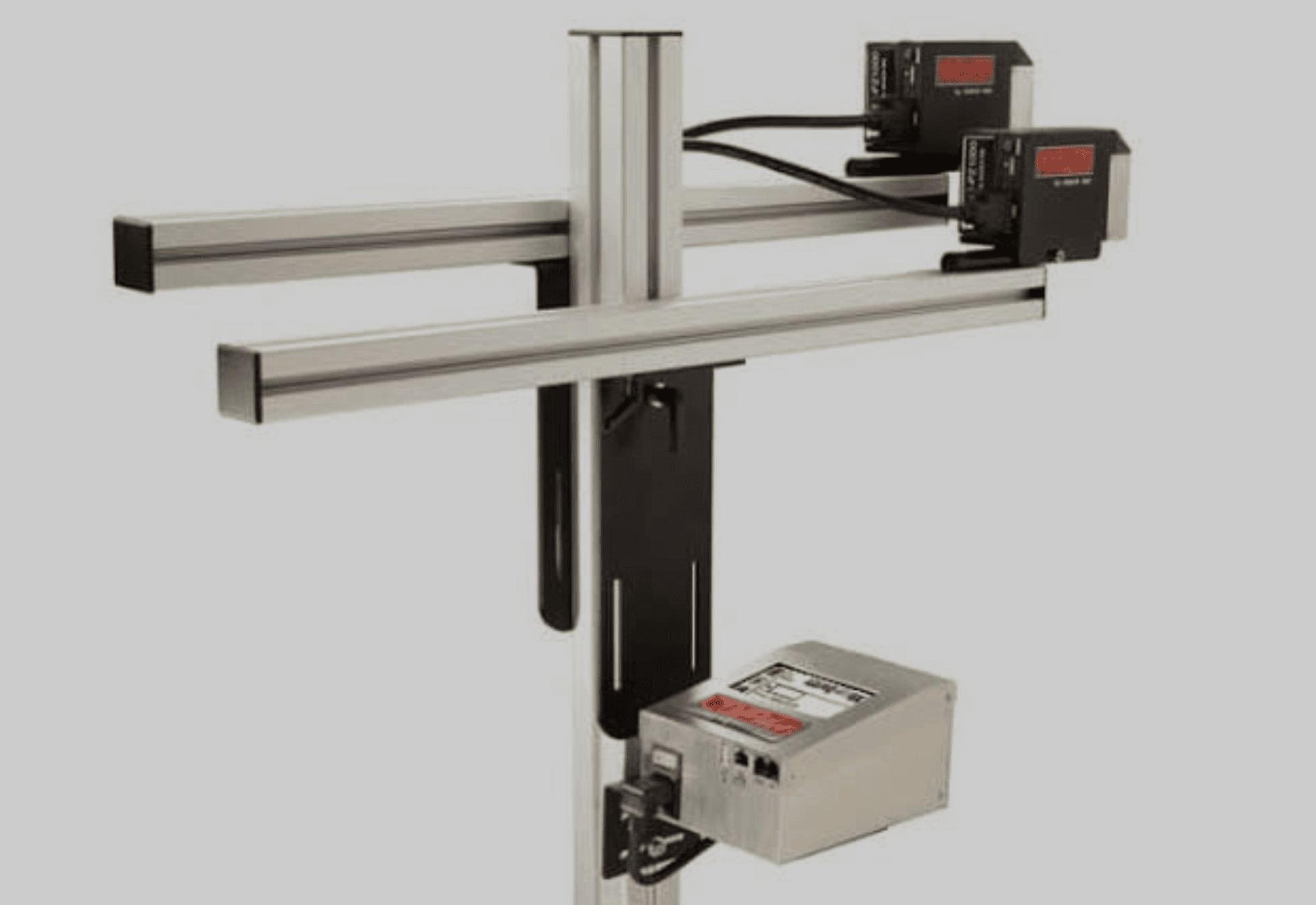

- Optical Instruments & Vision Systems

Optical Instruments / Vision Systems

Unity can produce small, precise components for optical instruments and vision systems.

- Printing

Printing

We collaborate with printing companies to produce precision parts for dot matrix printers and other types of equipment.

- Sporting equipment

Sporting equipment

We produce components for mechanical equipment commonly used in various sports.

- Automotive

Automotive

Our manufacturing expertise allows us to deliver durability and precision in the components we produce for the automotive industry.

Benefits of Contract Manufacturing With Unity

The following advantages of contract manufacturing can be achieved by partnering with Unity.

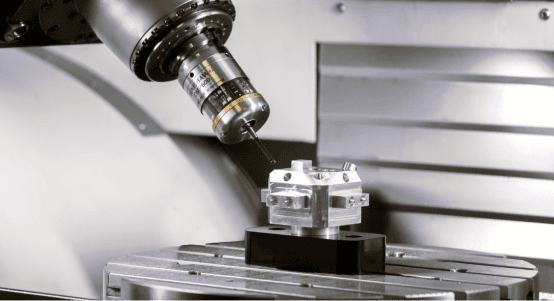

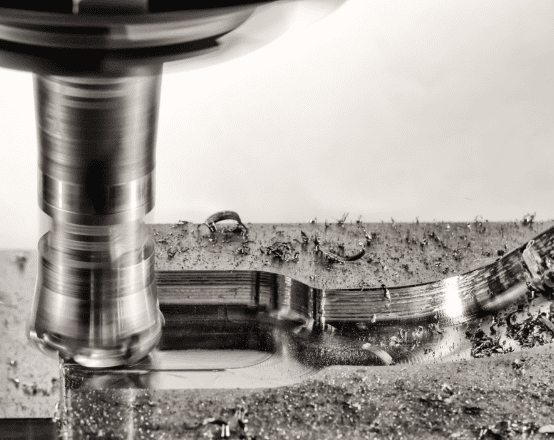

Advanced Manufacturing Capabilities

With over five decades of proven experience, Unity has the expertise to deliver industry-specific contract manufacturing solutions that adhere to all regulatory standards and requirements. By using the following advanced manufacturing processes, we can handle the demands of complex projects with unique material specifications:

- CNC milling

- CNC turning

- Swiss machining

- Assembly

- Kanban

Cost Reduction

We’re able to offer customers competitive pricing because of our:

- Automation. We have automated production lines for maximizing efficiencies, leading to better pricing.

- Lower overhead. Commercial contract manufacturing lowers overhead by eliminating the need for companies to make considerable investments in in-house equipment, skilled personnel, and manufacturing facilities.

- Reduced labor costs. Our Minnesota-based operations offer lower labor costs compared to production regions with higher labor costs.

Customer-Centric Approach

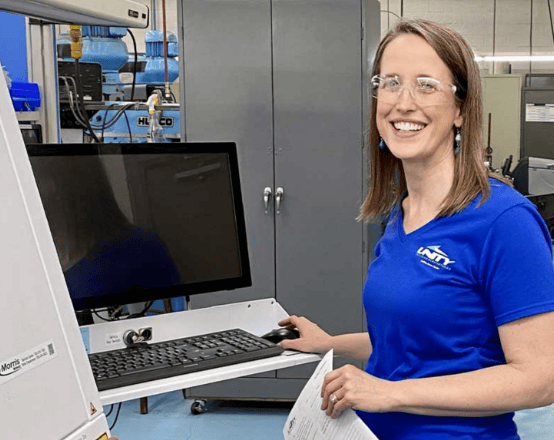

Unity takes a customer-first approach to our commercial contract manufacturing solutions, focusing on developing strong, long-lasting partnerships. Our experienced team works closely with our clients throughout the manufacturing process to meet their specific expectations and needs.

Customers Can Focus on Core Competencies

By handling all manufacturing processes, we free up our customers to focus on and streamline their core competencies, such as sales, marketing, and product design. Our commercial contract manufacturing solutions also reduce the stress of managing daily manufacturing operations.

Increased Scalability and Flexibility

With our scaling capabilities, production volumes can be increased or decreased to meet fluctuating demand. Plus, our customers can quickly introduce new products to the market without the delays associated with designing and building manufacturing facilities.

Non-Stop 24-Hour Production

We have state-of-the-art equipment, which includes automated robotic centers that work 24 hours a day from our modern, sustainable, and temperature-controlled facility.

On-Time Delivery

Our 24/7 operations and streamlined production processes allow us to deliver projects on time, including those with tight schedules.

Unsurpassed Quality and Precision

Unity is ISO 9001 and ISO 13485 certified, dedicated to delivering consistently high-quality products with unmatched precision. Our components can meet tight tolerances to ±.0001″, which we can inspect and verify through our robust quality control processes. We also provide Certificates of Conformance and other documentation as needed. This includes full traceability documentation from material procurement to final product testing.

Ready to Partner with a Trusted Commercial Contract Manufacturer?

At Unity, we believe in unifying all aspects of precision machining to provide commercial contract manufacturing solutions that meet or exceed our clients’ expectations. As a third-generation family-owned company founded in 1969, Unity is committed to forging lasting client relationships based on trust, transparency, and robust manufacturing capabilities.

With modern facilities, advanced equipment, validated quality processes, and dedicated staff, Unity can handle the complex needs of a broad range of industries and applications, from commercial machinery components to sporting equipment parts. Partnering with us will help you lower costs and scale production as needed so you can focus on your core business.

Contact us today to find out how our commercial contract manufacturing solutions can meet your project requirements.